Brilliance and Durability: Ceramic Coatings for Everyone

HPC 2.0

Super water-repellent nanotechnological protection

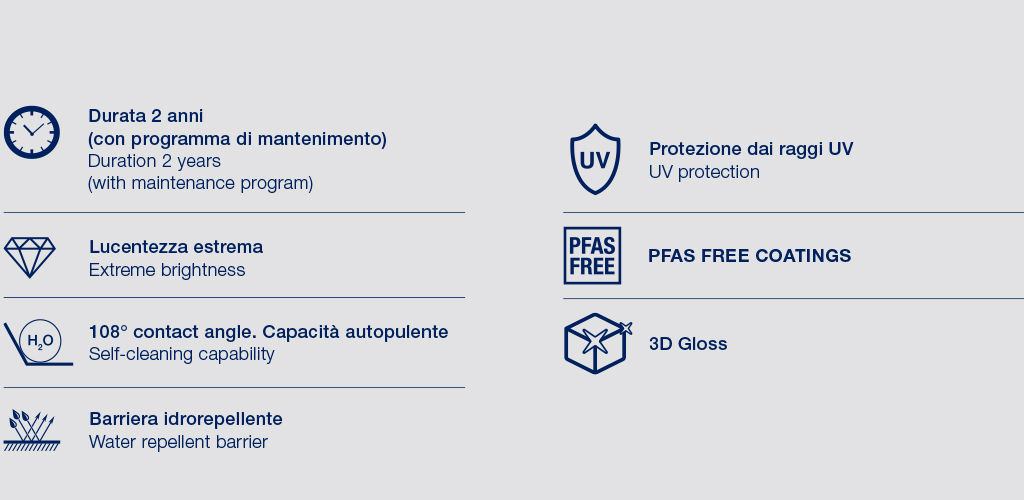

HPC 2.0 is a hybrid technology coating composed of a blend of polysiloxane and new generation polymers. It guarantees a duration of up to 24 months or 30,000 km.

HPC 2.0 represents a step forward in the study and formulation of new generation hybrid coatings. Compared to the previous version, thanks to advanced research in the world of polymers, and specifically Polysiloxane, its formula establishes a new standard in the world of protective coatings for cars.

This combination of polymers not only ensures a high quality super hydrophobic protective coating, but the “silk” feel to the touch and the extraordinary self-cleaning capabilities drastically reduce the risk of scratches, especially during the hand washing phase, maintaining the car in impeccable condition for longer.

Easy to apply and with fast drying times, HPC 2.0 is designed to offer maximum comfort and efficiency, allowing you to achieve exceptional results with minimal effort.

WHAT THEY ARE AND WHAT IS THE DIFFERENCE BETWEEN POLYSILOXANE AND POLYSILAZANE POLYMERS

Polysiloxane

Polysiloxanes are inorganic polymers that contain a backbone of silicon and oxygen (Si-O) atoms, also known as silicones. Polysiloxanes are appreciated for their flexibility, resistance to low temperatures, water repellency and insulating properties.

Polysilazane

Polysilazane, on the other hand, is a type of inorganic polymer that contains both silicon (Si) and nitrogen (N) in its basic structure. These compounds are known for their excellent thermal and chemical resistance properties, as well as their abilities to form hard, protective coatings.

Due to these characteristics it is often used in the aerospace sector for protective coatings of components that must resist extreme environmental conditions

The main difference between the two lies in the chemical composition and the resulting properties.

Polysiloxanes, with their Si-N structure, tend to offer greater hardness and thermal resistance than Polysiloxanes, making them particularly suitable for applications requiring high-performance protective coatings. Polysiloxanes, with their Si-O structure, are more flexible and insulating, making them ideal for highly water-repellent protective coatings for clear and long-lasting beeding and sheeting.

HPC 2.0

PFAS FREE:

Your health is more important than any result. The entire Labocosmetica collection is free of PFAS or Forever Chemicals.

Extreme ease of use:

also designed for those who have never applied a coating in their life.

Without streaks:

the new HPC 2.0 formula guarantees uniform application and easy removal, without leaving traces.

Reduces the possibility of creating scratches and abrasions thanks to the smooth and silky finish that lasts for up to 24 months or 30,000 km

Dust Out Technology:

Allows application in open places, ideal for those who work in mobile detailing.

Greater Economy:

Reduced consumption of cloths for removal during application, requiring fewer microfiber cloths for treatment.

Save time and effort:

it can now be applied by proceeding on larger surfaces, up to 60×60 cm, compared to previous coatings even with faster movements. Application and removal are quick and simple, for flawless results in just a few steps.

HPC 2.0

Superior silkiness:

Gives an ultra-smooth and silky finish to the treated surface, improving the aesthetic appearance and pleasantness to the touch.

Versatile:

can be used as a stand alone coating or as a top coat

I forgive you technology (error tolerance):

did you do something wrong during the application? No problem! HPC 2.0 allows you to fix errors even after several hours.

Material Economy:

HPC 2.0 requires less use of microfiber cloths for removal, thanks to its new, more efficient formula

Perfect for opaque cars:

it does not change the finish of the bodywork and the color saturation even if it is overlapped during application

Three-dimensional gloss:

amplifies the particularity of the car’s color to the point of making it appear three-dimensional

HPC 2.0

How It Works

For best results, it is essential to properly prepare the car’s surface, making sure it is clean and dry.

Apply HPC 2.0 evenly, following the specific instructions provided in the package for drying times and application methods

Recommendations

Make sure the surface is totally clean and free of contamination.

Remove any residue of previous coatings, waxes and paints before proceeding with the application

In case of scratches, swirls and holograms, it is necessary to proceed with a mechanical polishing of the surface.

The surface must be adequately degreased with Veritas before applying the coating

If you wish to apply a second layer of coating as a top layer, avoid degreasing the surface over the previously applied coating.

Read the precautions and instructions on the packaging carefully before use. Store the product in a safe place, out of the reach of children and in optimal conditions to ensure its preservation.

HPC 2.0

SAM

STAND-ALONE COATING

SAM is a type of stand-alone coating which, thanks to the Self Assembled Monolayer technology on which it is based, can be applied as a single layer, guaranteeing effective chemical-physical protection on any type of bodywork.

The excellence of the #Labocosmetics Line in terms of durability and performance.

SAM is a type of stand-alone coating which, thanks to the Self Assembled Monolayer technology on which it is based, can be applied as a single layer guaranteeing an effective chemical-physical protection on any type of bodywork. SAM, once applied to the surface, spontaneously forms a coating thanks to the chemical absorption and self-organization of organic molecules composed of ” Head Groups ” reactive and from chemical groups called” functional “selected (functionalized molecules) in order to obtain the best balance between physical protection and hydrophobic performance.

Application on specially prepared surfaces is necessary to “free” the surface active sites with which SAM will form a stable chemical bond and thus obtain the best possible yield in terms of efficacy and durability.

SAM

SURFACE PREPARATION:

An accurate preparation of the surface to be treated is essential for the correct fixing and maintenance of the coating. We recommend that you always observe these simple rules:

- the surface must be decontaminated and free from any residue;

- remove old waxes from the surface , sealants or coatings before proceeding;

- the surface must be perfectly free from surface scratches, marks and stains which, if present, must be removed with a polisher;

- if you are working with a new car that does not require corrective paint work, proceed with a decontaminating wash to remove any residues from transport;

- the bodywork must be completely degreased : use Vèritas in the dilution 1: 5 before applying the coating. This step is mandatory!

APPLICATION TIPS:

Always apply the coating in covered and dust-free environments , never outdoors. We recommend the use of PPE (Personal Protective Equipment) in this case the solvent steam mask. Never work in direct sunlight. Make sure the work area is well ventilated. There are two main factors that influence the application of coatings: temperature and humidity . The higher the temperature and / or humidity , the shorter the coating installation time. We suggest

to work on small sections of maximum 50x50cm . It is essential to use correct lighting. Apply the coating using reflected lights. Point your lamp at the wall or ceiling – this will help you spot possible smudges that you will need to remove immediately . The initial fixing time of the SAM and HPC coatings of #Labocosmetica with the treated surface is a few minutes : therefore use microfibre cloths to eliminate residues and carry out the finish. Make sure that the car remains in optimal conditions without the risk of rain or sudden changes in humidity: the curing time necessary to allow the partial closure of the coating takes place within 12 hours , while the total one takes place within 36 hours and it is advisable not to wash the car for the first 7/10 days. If you have an infrared lamp, place it at a distance of 50cm for about 15-20 minutes at 60 ° C temperature to fix the coating to the surface. Always respect the application instructions of the individual products.

Safety: it is PFAS free and compliant with the content of volatile organic components (VOC) according to Directive 2004/42/EC and with the analysis method compliant with UNI EN ISO 11890-1 :2008.

STAND-ALONE

SAM is a type of stand-alone coating which, thanks to the “Self Assembled Monolayer” technology on which it is based, can be applied as a single layer ensuring effective chemical-physical protection on any type of bodywork.

SAM

2 YEAR DURATION

SAM forms a bond stable chemical and thus obtain the best made possible in terms of effectiveness and duration.

- Duration 2 years

- 108° contact angle. Self-cleaning capability

- 3D Gloss

MIRROR LIKE EFFECT

The #LABOCOSMETICA® system provides a unique silky, mirror like effect on treated surfaces. Surfaces are so smooth that dirt can no longer adhere onto them: this is the Lotus Effect system.